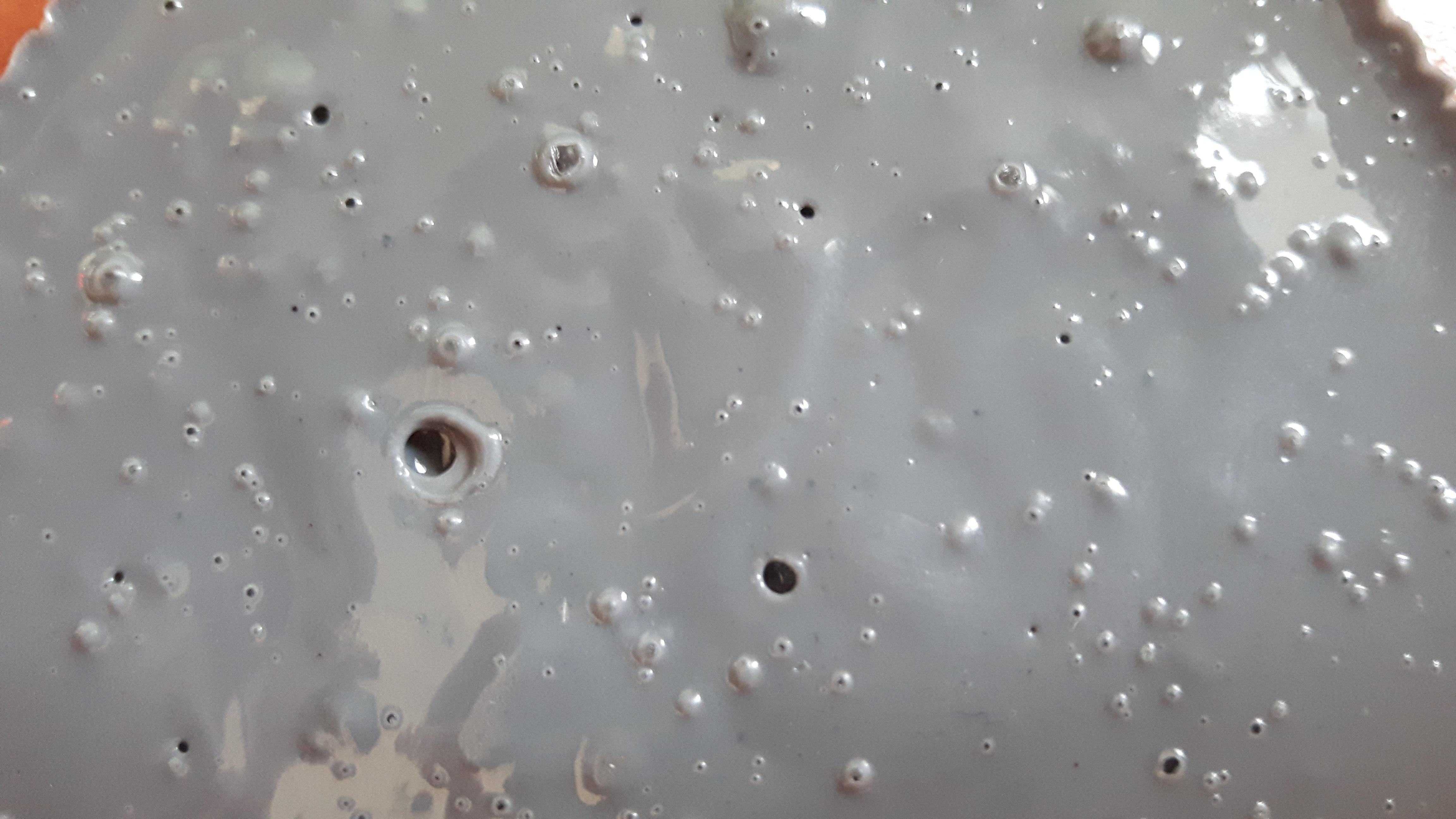

Do you know how to avoid air bubbles in a thermosetting resin? As bubbles may arise for different reasons, here are some tips to control the phenomenon

1. Take the mixture seriously !

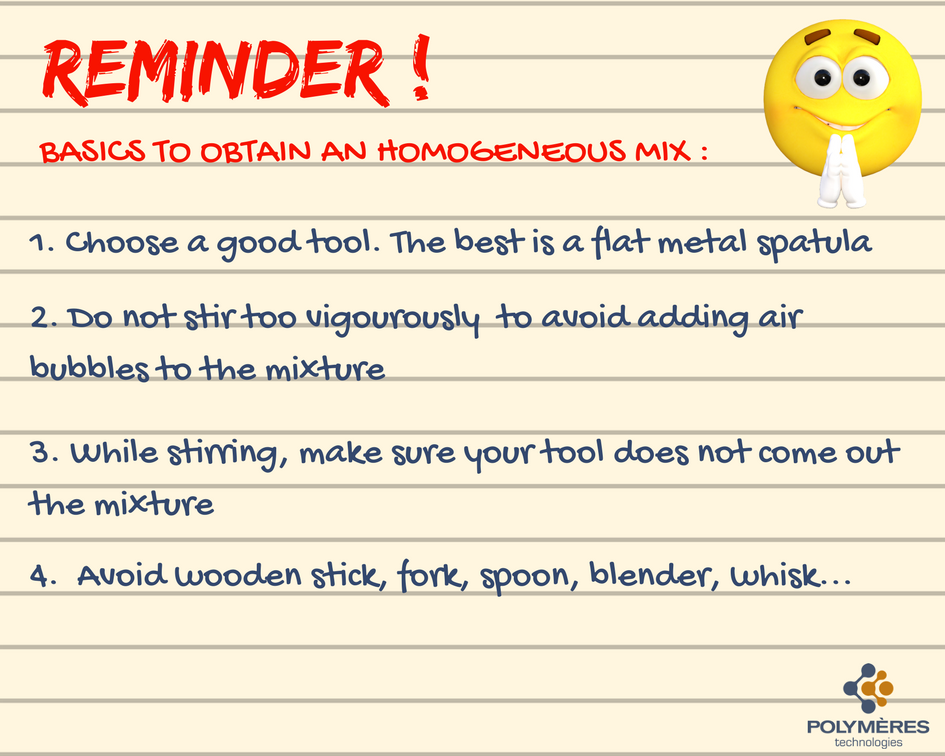

First and foremost, air bubbles is often induced when mixing part A and part B. That is why we advise to stir gently forming an eight shape, making sure your tool does not come out your container. Stir until the mixture is perfectly homogenous

Avoid stirring vigourously because it might create a vortex, inducing air bubbles in the mixture that would grow and appear when heat is generated by the chemical reaction when part A and part B are mixed.

For small amount of resin, using a one inch large flat metal spatula is recommanded. Do not use a wooden stick as wood porous and may contain humidity that can affect and irreversibly damage polyurethane resins.

For bigger amount of resin, make sure to select a mixer with the appropriate size. The head of the mixer should always be fully immersed in the mixture.

Let the mixture degaze naturally before applying or casting the resin. Be careful, though, the more you wait , the thicker the resin becomes *.

2. Consider the surface to be covered or the master .

Air bubbles may come out of the surface to be covered or the master.Indeed, humidity can be captured in some porous materials As polymerization is induced by heat reaction (exhotherm), it creates bubbles that try to escape the material.

As a consequence, it is highly advised to sealed your material before applying the resin.

For instance, If you apply an epoxy resin on a canva, you can apply a thin layer of resin that will play the same role as a sealant. In that case, you do not need to wait until the layer is completely dry. You can apply your resin when it is still a little bit sticky (in French, the resin is said to be “amoureuse” : ♥ )

If the resin is casted in a mold, make sure to clean the mold in order to remove any dust, residues or humidity.

3. Other parameters under control

Others points should be considered but they greatly depend on the kind of resin is used.

Working environment

Some resins are more sensitive to humidity, notably polyurethanes. It is important to work in an environment where humidity rate is maintained under 60%.

Viscosity

The more liquid the resin, the easier and faster air bubbles come out the surface. By contrast, a thicker resin (with higher viscosity) air bubbles do not come out easily.

Resin layer thickness

Generally speaking, air bubbles will come out of the resin more easily when the layer is thin. The thicker, the more difficult it is for the bubbles to come out naturally. It might be a good solution to cast several layers of resin to allow air bubbles to come out between each casting.

For the same reason, we recommand that the container used to mix part A and part B should be wider than high.

NB: the maximation duration to let the bubbles come out naturally depends on the pot life of your mixture . To put it in a nutshell, the pot life is the time for which the product can be used once it has been mixed. It varies upon the amount mixed and the temperature.