Resin preservation during winter?

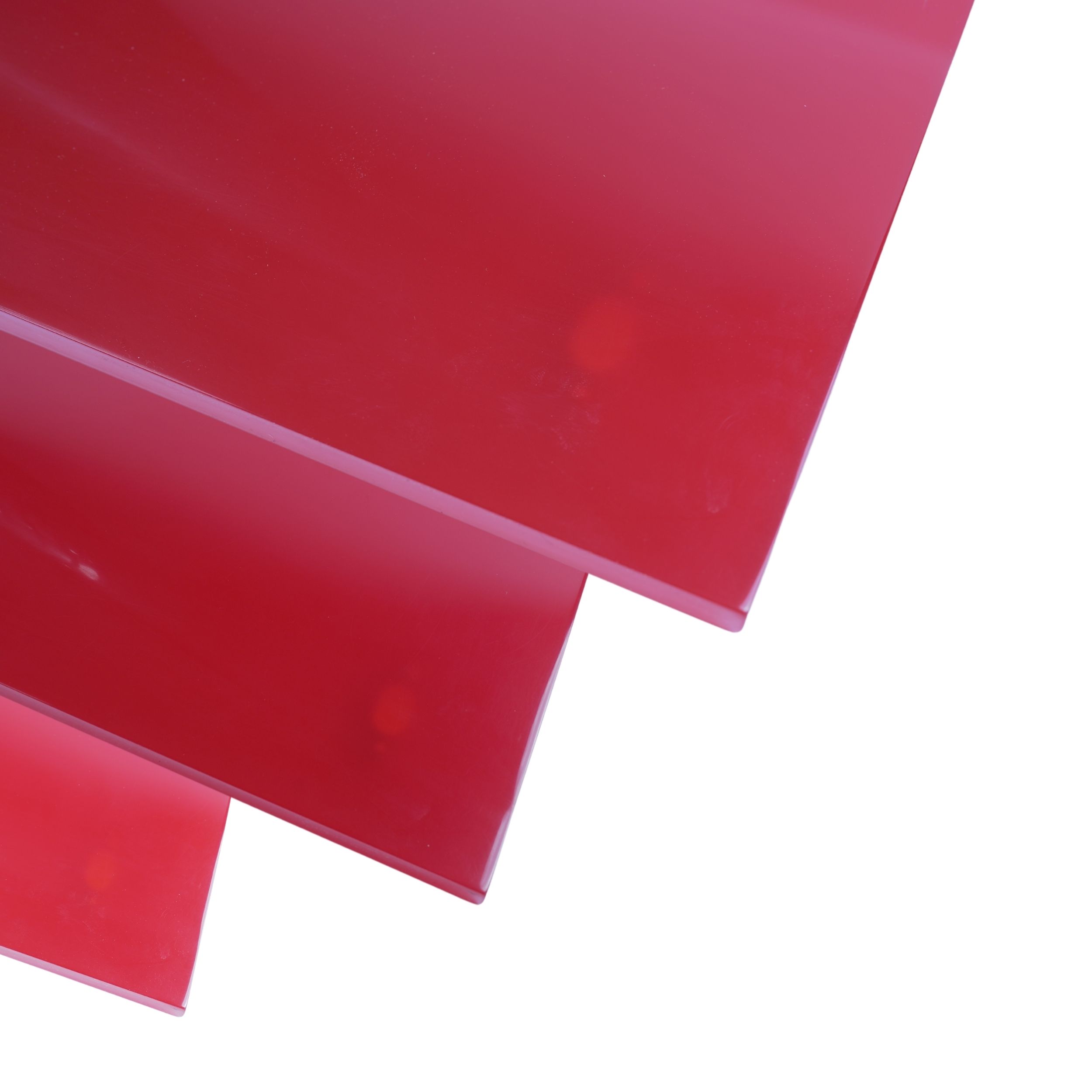

Resin preservation during winter? Did you know that cold temperatures could prevent you get good results when working with thermoset resins? In this article you will learn more on why storage conditions can affect the characteristics and quality of your resin and what precautions should be taken when winter is coming….

Resin preservation during winter?

Why cold weather could affect your thermoset resins?

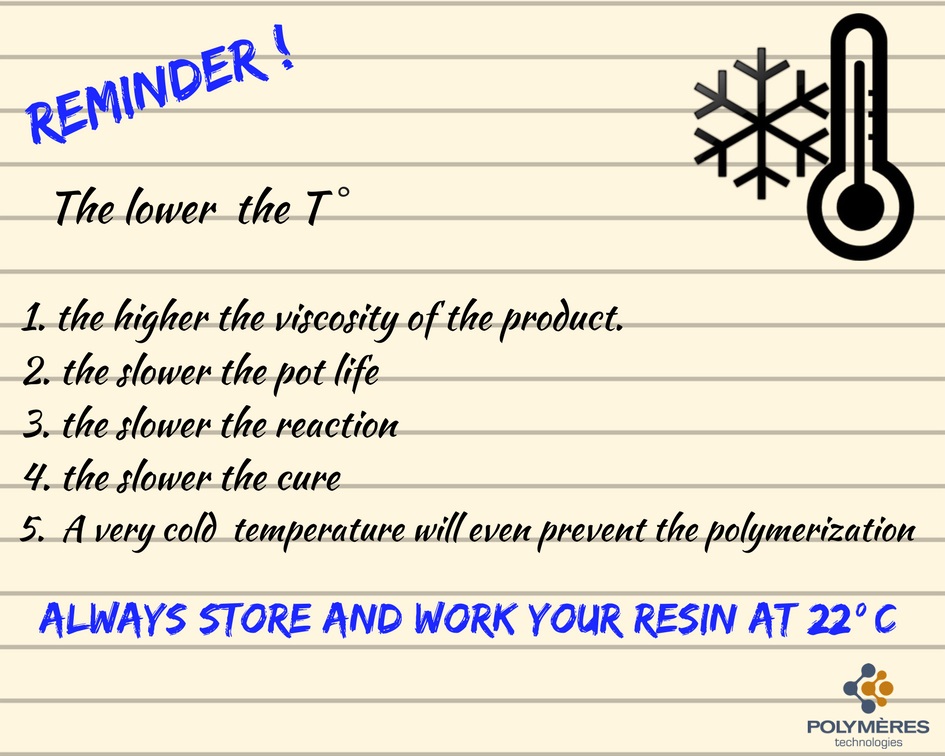

First of fall, thermoset resins, be it epoxy, urethane or silicone, can be greatly affected by cold temperatures. The logic behind this is very simple. For a resin to change state from a liquid to a solid, it takes a chemical reaction which is basically exothermic: meaning it takes heat to happen. In other words, a cold temperature will slow or even prevent the polymerization to occur. Consequently, when your resin is stored at temperature lower than 22°C, it dramatically changes the characteristics of the product ; the product thickens and reactivity (which is the capacity of the mixture of the resin and catalyst to create the heat/ explosion needed to start the reaction) is threatened.

In addition, when a resin contains fillers (for instance an epoxy resin which contains aluminum often used to pour thermoforming mold) additives tend to harden in the bottom of the container, creating “hard pack”. For the same reason, casting resin when the temperature is cold is not recommended. Working environment should always be kept at 22° Celsius.

What should you do to protect your resin?

It is very important to store your containers on pallet in an environment at 22 degrees Celsius. Keep them away from outdoor entrance, particularly in winter.

Shall I tell you a story that happened once to one of our customer. We should mention this customer was not a rookie and had yet quite a long experience with thermosetting resin. We were in February and he reported that he encountered troubles casting the resin that would not catalyse. At first he could not understand what was going on because he pretended to be cautious with the working conditions. After a while, it appeared that the heat in the facility was turned off at night, thus preventing the polymerisation to succeed.

So be absolutely sure your ambient temperature is always kept at 22° C on days and nights.

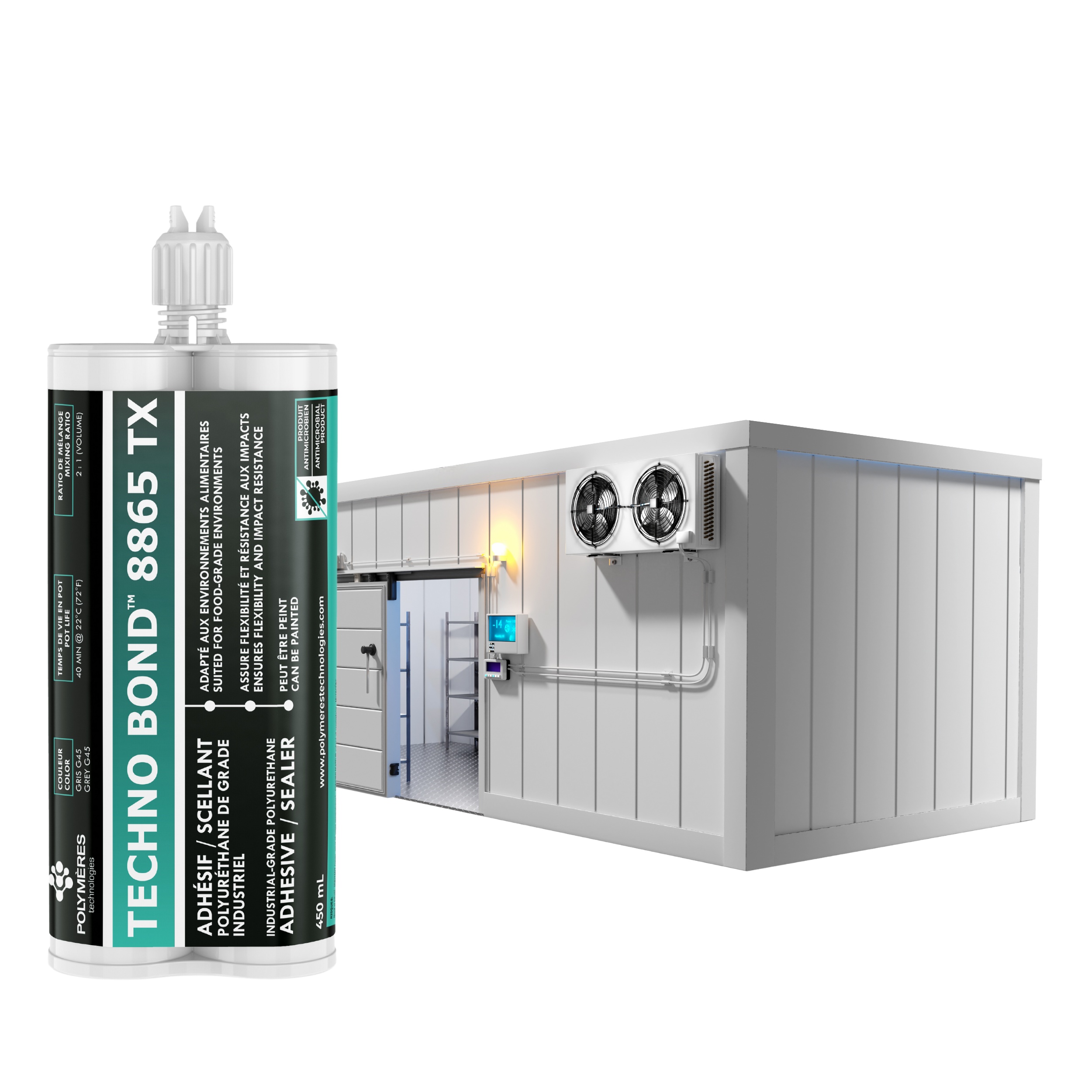

Besides, when you work with polyurethane, check the humidity rate. It should not exceed 60%. Indeed, as the hardener or part B, contains isocyanate which is a very sensitive product to moisture. Contaminated product swells and is unusable.

Once you pour the mixture, make sure to close immediately the containers. To prevent the contamination, nitrogen can also be sprayed to part B. It will create a protective barrier between the product and the lid.

Winters in Canada do not let us be negligent when it comes to work with thermosetting resin…Be sure to take all necessary measures to prevent bad surprises…